Machine vision is a hot term in nearly every industry today, but many business leaders have no idea what it actually involves or how it works.

This concept is simultaneously simple and complex. At its most basic level, it involves a digital version of human visual perception. Below, we’re going into specifics of how it works, the benefits of using it in the supply chain and logistics sector, and how to best leverage this technology in your business operations.

What is Machine Vision Technology?

Machine vision (MV) technology encompasses all of the devices and systems required to both capture and perceive images digitally. These systems consist of digital sensors found within industrial cameras. The software involved in this system is just as important as the cameras themselves, however, as this is what allows MV to so accurately mimic human perception.

How Does It Work?

Now that you have a basic idea of what machine vision technology is, it’s time to dive into the details of how, exactly, it manages to accomplish what was previously limited to the human eye.

Digital Sensors Capture Light

Machine vision systems rely on image sensors, which are capable of detecting when packages, pallets, or other objects are present. These sensors can capture light via complementary metal–oxide–semiconductors (CMOS) or charge-coupled devices (CCD). Both CMOS and CCD make it possible to convert captured light to pixels. These pixels, in turn, demonstrate when light is present in specific areas.

These vision sensors with higher resolutions are typically able to produce images that contain more pixels. This promotes better image quality and makes it easier to discern visual details.

Frame grabbers help to capture high-resolution images in a variety of settings. These components obtain still frames in digital form, often performing real-time compression or otherwise preparing images for analysis. These can be used in place of or alongside smart cameras.

Vision Processing

Vision processing follows sensor detection. This technological component of the MV system draws on data produced by the digital images the sensors captured. Pre-processing may be required to optimize images for the purpose of measurements.

Next, the image must be analyzed to determine which features will need to be measured or observed. Once necessary measurements have been collected, they may be compared against defined criteria.

Ethernet Connections

When considering the possibility of implementing MV systems, many business leaders neglect to consider how, exactly, the systems will transmit real-time data. Many enterprises rely on Ethernet for this function, as this connects machine vision components directly to essential hubs — and allows them to interact with all other network devices. Efficient and effective communication is essential, especially as more MV systems move from analog to digital.

Machine Vision Plus Barcode Scanning

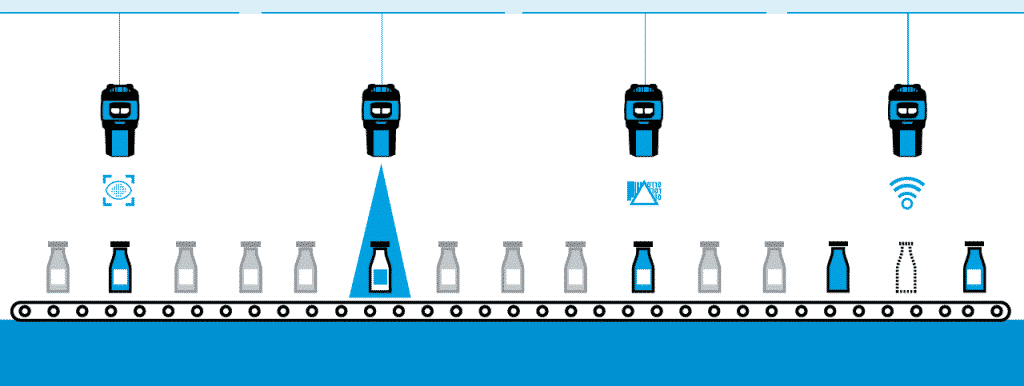

In logistics, machine vision is often used alongside barcode systems to provide an alternative to traditional employee-based scanning. This may be powered by Optical Character Recognition (OCR), which allows machine vision systems to make judgments based on data extracted from captured images.

Before MV solutions were implemented, barcode scanning typically relied on human labor. This prevented workers from focusing on other, higher-level tasks. Human-based barcode reading and verification are time-intensive and prone to errors, so the integration of machine vision has proven incredibly helpful.

Currently, optimized MV barcode scanning involves a series of strategically placed cameras, which can capture images from every pallet. These systems are particularly valuable prior to loading, as smart cameras minimize the likelihood of incorrect carriers or incomplete shipments.

What is Machine Vision Used for Today?

From health care to the automotive sector and even hospitality, machine vision can drive improvements in nearly every industry imaginable. At present, however, machine vision applications are most notable in supply chain and logistics operations.

We’ve already touched on the value of MV barcode scanning, but that’s only the beginning. Further industrial applications include:

- Pick and pack sorting. Vision-guided robotic sorting solutions can dramatically improve accuracy and efficiency for pick and pack operations. They’re particularly effective when integrated with industrial robots. Machine vision cameras can easily be implemented to ensure that all steps within automated workflows are completed properly. Also, as previously mentioned, these cameras are able to rapidly read barcodes situated on various sides of packages.

- Package tracking. Track and trace systems increasingly incorporate machine vision, which provides exceptional oversight as products navigate not only the warehouse environment, but also the entire supply chain. This functionality is especially important in food and beverage processing, where elite traceability makes it possible to determine the point of origin for all ingredients.

Quality control. Machine vision promotes nearly flawless quality control by removing the risk of human mistakes that commonly lead to returned orders. Robotic systems featuring machine vision excel as compared to their human counterparts. After all, while humans achieve a high level of discernment, their powers of perception can sometimes dull as a specific image is seen repeatedly and imprinted on the brain. Machine vision systems, however, capture accurate images every time. As such, MV solutions are already relied upon for everything from beer bottling to manufacturing, where they are able to close that defect detection gap.

Quality control. Machine vision promotes nearly flawless quality control by removing the risk of human mistakes that commonly lead to returned orders. Robotic systems featuring machine vision excel as compared to their human counterparts. After all, while humans achieve a high level of discernment, their powers of perception can sometimes dull as a specific image is seen repeatedly and imprinted on the brain. Machine vision systems, however, capture accurate images every time. As such, MV solutions are already relied upon for everything from beer bottling to manufacturing, where they are able to close that defect detection gap.- Safety verification and regulatory compliance. Similar to quality control, MV inspection systems may determine whether products or processes abide by safety protocol. For example, in food and beverage operations, machine vision systems may determine whether tamper-proof safety seals are present — and whether they’re used correctly.

The Future of this Technology

Machine vision has come a long way in the last few years, but its evolution is just beginning. Recent trends have included a shift towards the cloud, where high volumes of data generated are more easily accessible.

Cloud solutions enable enterprises to make better use of data generated via these systems, thereby ensuring that patterns are spotted and that these observations produce the necessary improvements. Cloud-optimized MV solutions also promote more efficient decision-making, as the cloud provides immediate access to real-time data.

MV technology is often highlighted as a key component of the expected fourth industrial revolution, which is typically referred to as Industry 4.0. Additional developments worth paying attention to include the following:

Alternate Lighting Solutions

In the not-so-distant future, machine vision may be functional in a greater variety of spaces, as it may no longer rely on light alone.

Already, near infrared (NIR) cameras are an option when a reliable light source is not available. NIR allows MV systems to perceive images in low-light settings, which are typically not conducive to accurate human sight.

NIR systems are distinct from far infrared in that they are capable of detecting photons and can therefore produce sharp, high-quality images.

Autonomous Vehicles

Machine vision could play a valuable role in promoting the use of autonomous vehicles within numerous contexts. For example, self-driving forklifts may become an integral part of the modern warehouse environment, providing much-needed support for packing and palletizing.

Artificial intelligence and advanced algorithms will further elevate these autonomous systems, allowing them to function according to self-collected data regarding warehouse layouts and typical traffic patterns.

Harness the Power of Machine Vision With Peak Technologies

As the technology that underscores computer vision becomes even more complex, it will be crucial to work with professionals who understand how evolving systems can be effectively implemented. Strategic integration is essential, particularly in any logistics operation that relies on automation.

Our team at Peak Technologies offers assistance for cutting-edge machine vision solutions and other technologies that promise to revolutionize the supply chain sector. Our field service engineers can help you determine which applications are most relevant to your enterprise — and how they can be implemented to deliver the highest possible ROI.

Customized end-to-end solutions should be tailored to the unique needs of every enterprise. At Peak Technologies, we guarantee personalized services that work effectively within your operations’ requirements. Contact us today to learn more about your options for integrating machine vision systems and other cutting-edge strategies.